Blast Chiller/Freezer 5 GN 1/1 - 600x400 - Built-in Motor

Environmentally-friendly R452A gas

Electronic control

SOFT COOLING +3°C WORKING CYCLE Gentle cooling cycle to bring the food to a core temperature of 3°C with a working cycle between 0°C and +2°C in the chamber, storage at +2°C. Cycle particularly suitable for delicate foods of small thickness such as: pasta, rice, vegetables, pastries, fish.

HARD +3°C COOLING WORKING CYCLE Particularly incisive cooling cycle to bring the food to a core temperature of 3°C following the following phases: 1st - Phase until 15°C is reached at the core with T° in the chamber of -25°C; 2nd - Phase until 3°C is reached at the core with working cycle between 0°C and +2°C in the chamber, storage at +2°C; Working cycle particularly suitable for cooling vacuum-cooked foods, meats, sauces , broths.

SOFT

Monocoque construction in AISI304 Scotch-Brite satin stainless steel

Internal rounded structure in AISI 304 stainless steel

Internal molded bottom with central drain

PU, HCFC free insulation, thickness 60 mm, density 42 kg/m3

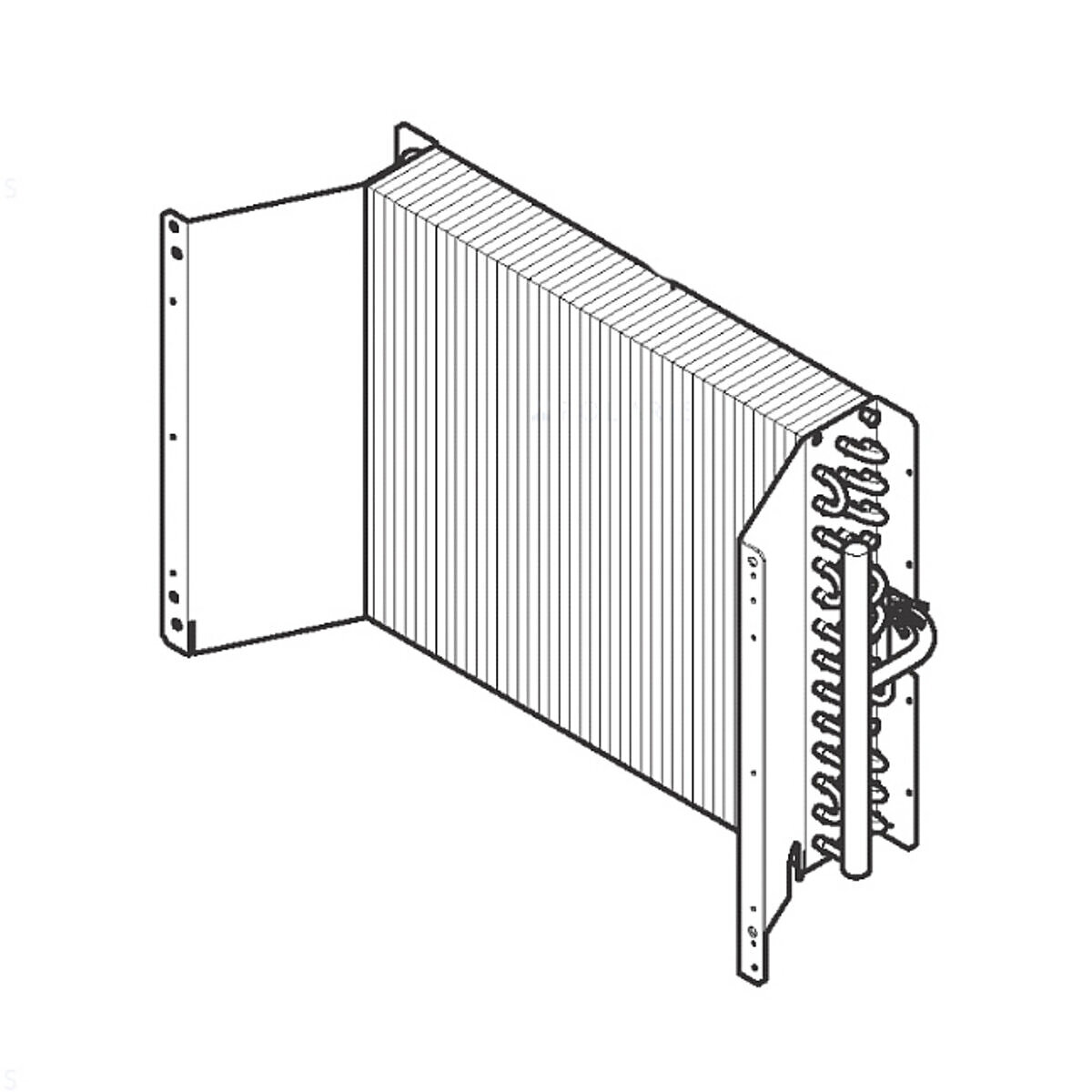

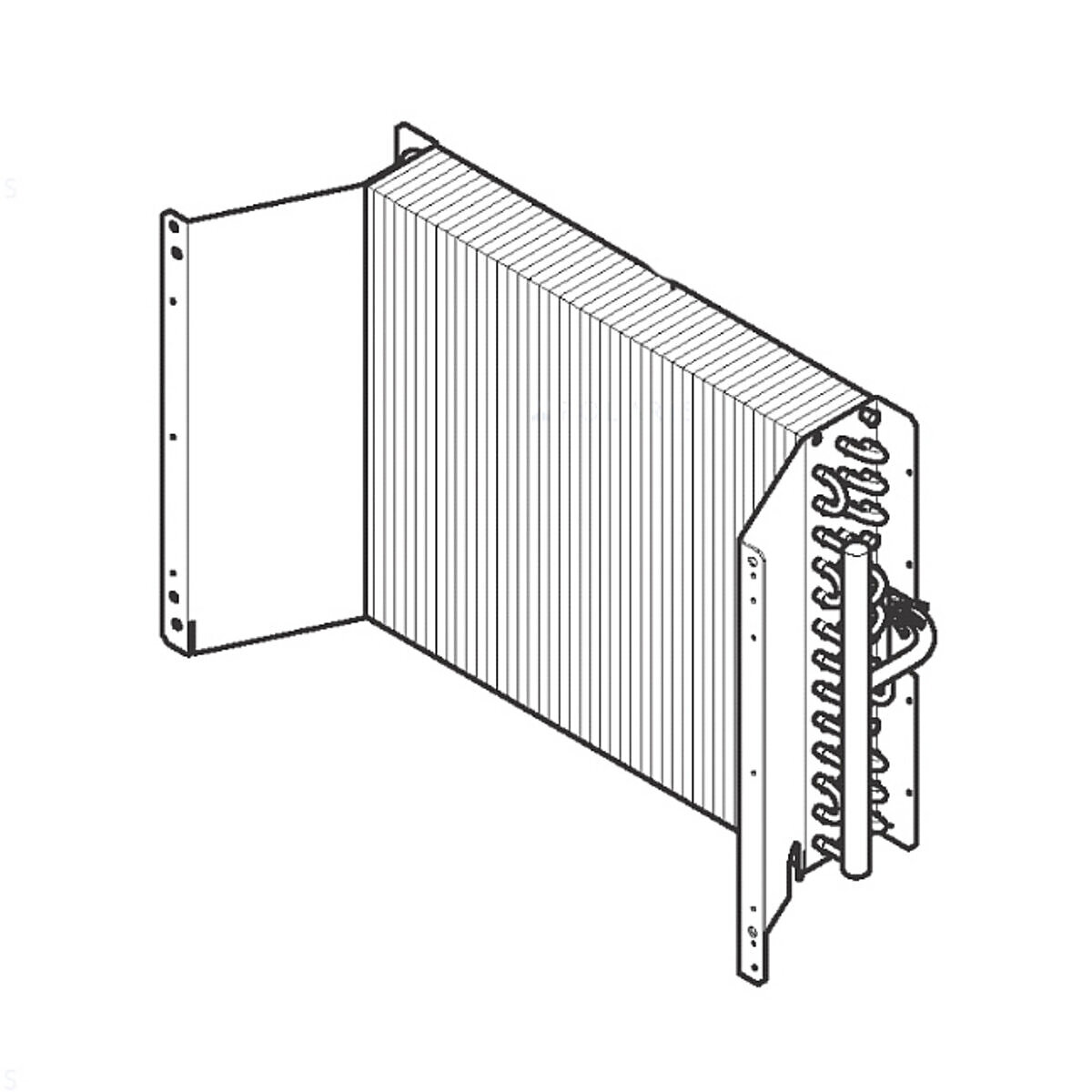

Evaporating coil in copper-aluminum, with anticorrosion cataphoresis treatment, with opening deflector for inspection

Anti-condensation resistance placed under the frame of the stop

Ergonomic full-height handle and magnetic seal on 4 sides of the door

heated single point probe

Manual defrosting device

Electronic fans

Environmentally-friendly R452A gas

Electronic membrane control. Front-mounted, easy-access IPX4 organized control panel.

Environmentally-friendly R452A gas Electronic control SOFT COOLING +3°C WORKING CYCLE Gentle cooling cycle to bring the food to a core temperature of 3°C with a working cycle between 0°C and +2°C in the chamber, storage at +2°C. Cycle particularly suitable for delicate foods of small thickness such as: pasta, rice, vegetables, pastries, fish. HARD +3°C COOLING WORKING CYCLE Particularly incisive cooling cycle to bring the food to a core temperature of 3°C following the following phases: 1st - Phase until 15°C is reached at the core with T° in the chamber of -25°C; 2nd - Phase until 3°C is reached at the core with working cycle between 0°C and +2°C in the chamber, storage at +2°C; Working cycle particularly suitable for cooling vacuum-cooked foods, meats, sauces , broths. SOFT FREEZING WORKING CYCLE -18°C Gentle freezing cycle to bring the food to a temperature of -18°C at the core, which includes the following phases: 1st - Phase until 20°C is reached at the core with T° in the cell at 0°C; 2nd - Phase until -18°C is reached at the core with T° in the cell of -40°C, storage at -20°C; Working cycle particularly suitable for all hot products that are intended to be frozen immediately. HARD FREEZING WORK CYCLE -18°C Particularly hard freezing cycle to bring the food to a core temperature of -18°C, with a work cycle that can reach -40°C. Work cycle particularly suitable for freezing raw or cold products.

Electronic membrane control. Front-mounted, easy-access IPX4 organized control panel.

AISI 304 stainless steel plate-rack support, with removable ANTI-BRIEFING pairs of AISI 304 stainless steel rails, interlocking positionable every 20 mm for GN1/1 or 600x400.

Heated core probe with 1 measuring point.

Copper-aluminum evaporator coil, with anticorrosive cataphoresis treatment, with flag-opening baffle on hinges, for cleaning

BE051

BN2ABF550301

Data sheet

- Model

- BE051

- Code

- BN2ABF550301

- Definition

- ABBATTITORE/SURGELATORE 5 GN 1/1 - 600x400 - MOTORE A BORDO

- Width

- 790mm

- Height

- 850mm

- Depth

- 800mm

- Electrical power

- 1.523Kw

220-240 V ~ 50 Hz - Gross volume

- 0.67

- Net weight

- 90Kg

- Gross weight

- 90Kg

- Capacity

- 109

- Packaging width

- 850

- Packaging height

- 995

- Packaging length

- 790

- Alimentazione

- ELETTRICA

- Gas/refrigerant type

- R452a

- Cooling power

- 2.169W

English

English