FRY TOP S Electric M40 Iron Plate - RIBBED - Thermostated Top Version

The GraphiTherm gasket, made of high-quality fiberglass and treated with graphite, withstands extreme temperatures and ensures effective sealing even in demanding conditions, protecting the fry top with safety and reliability.

Industry 4.0 ready version.

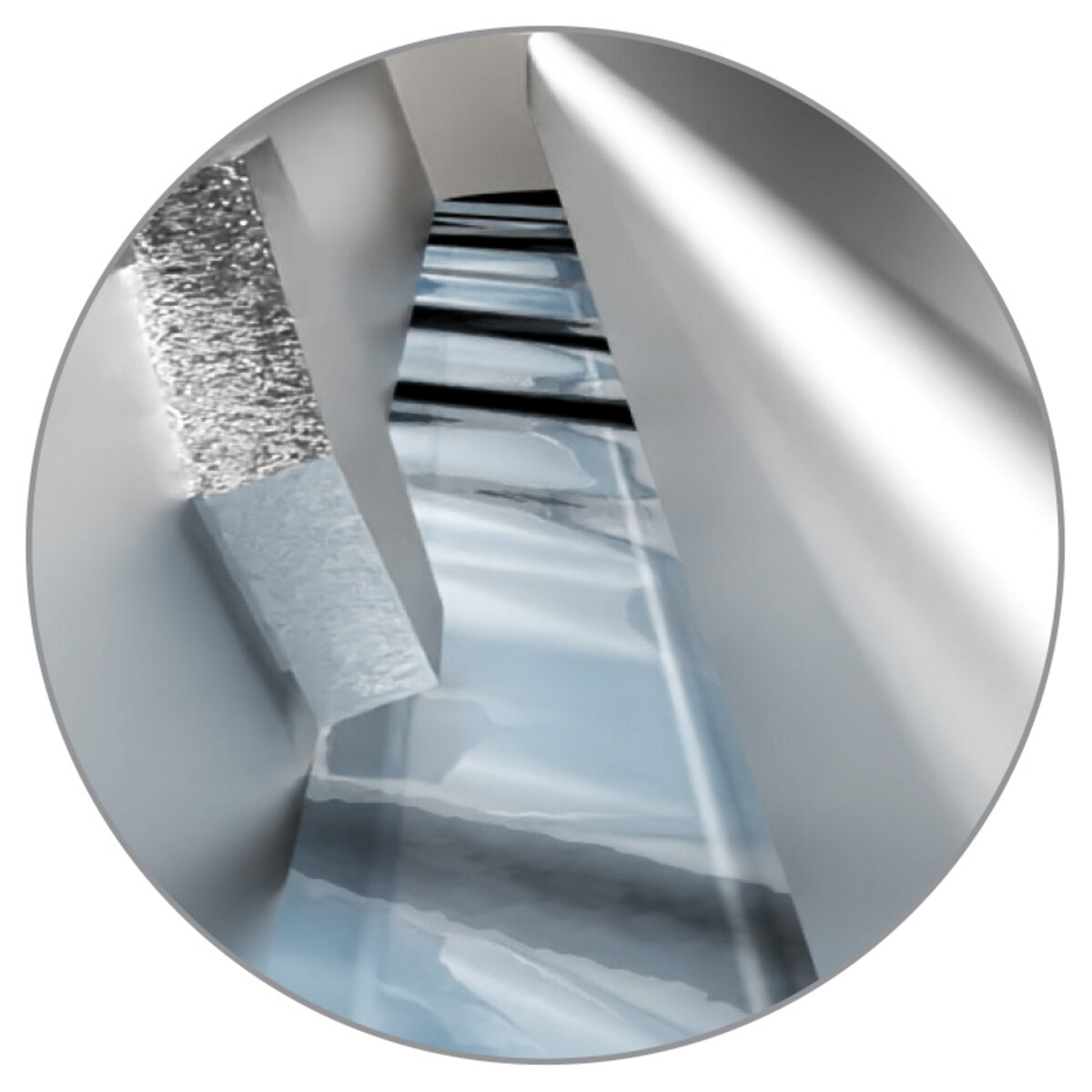

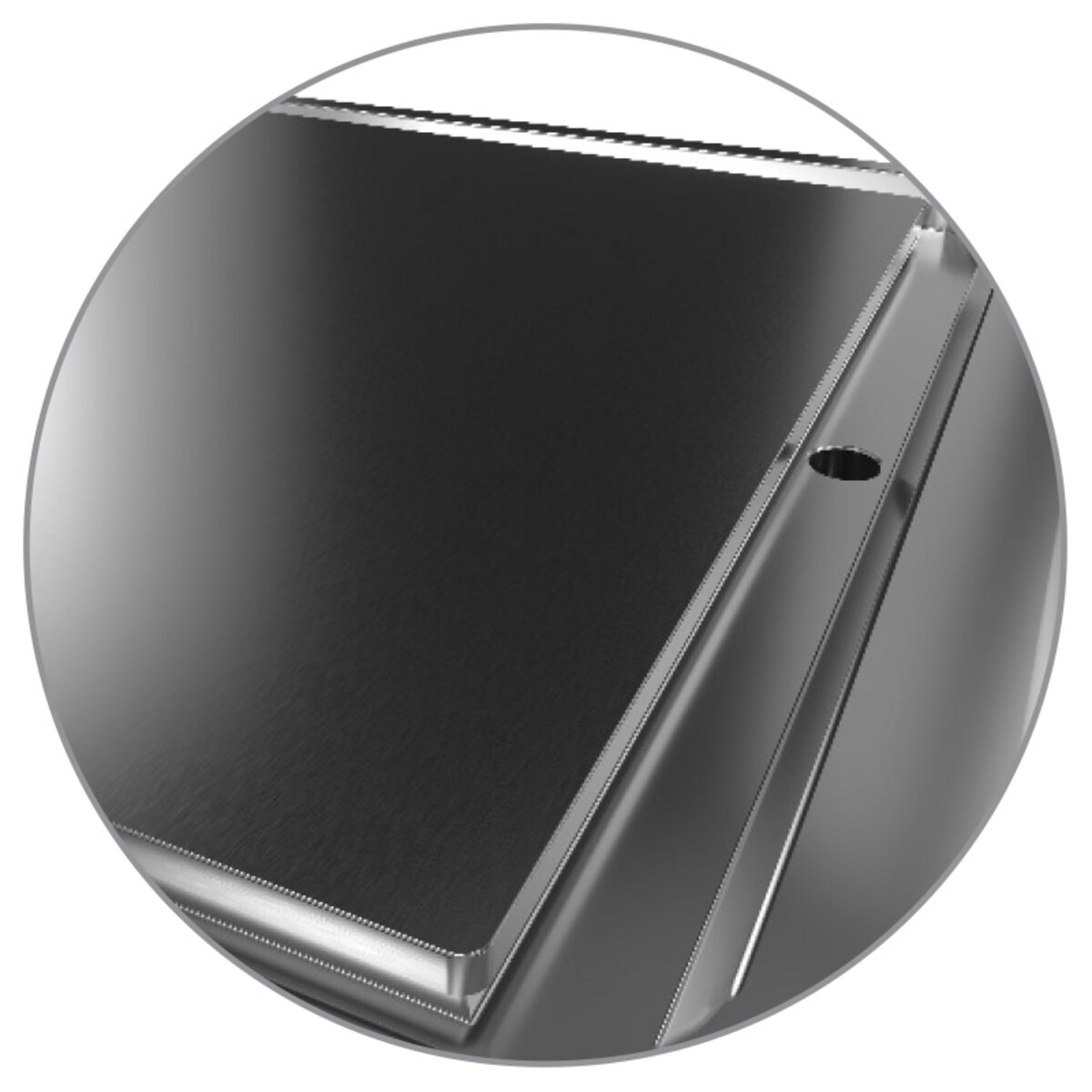

Grooved plate design ensures cleanliness right to the end of the plate

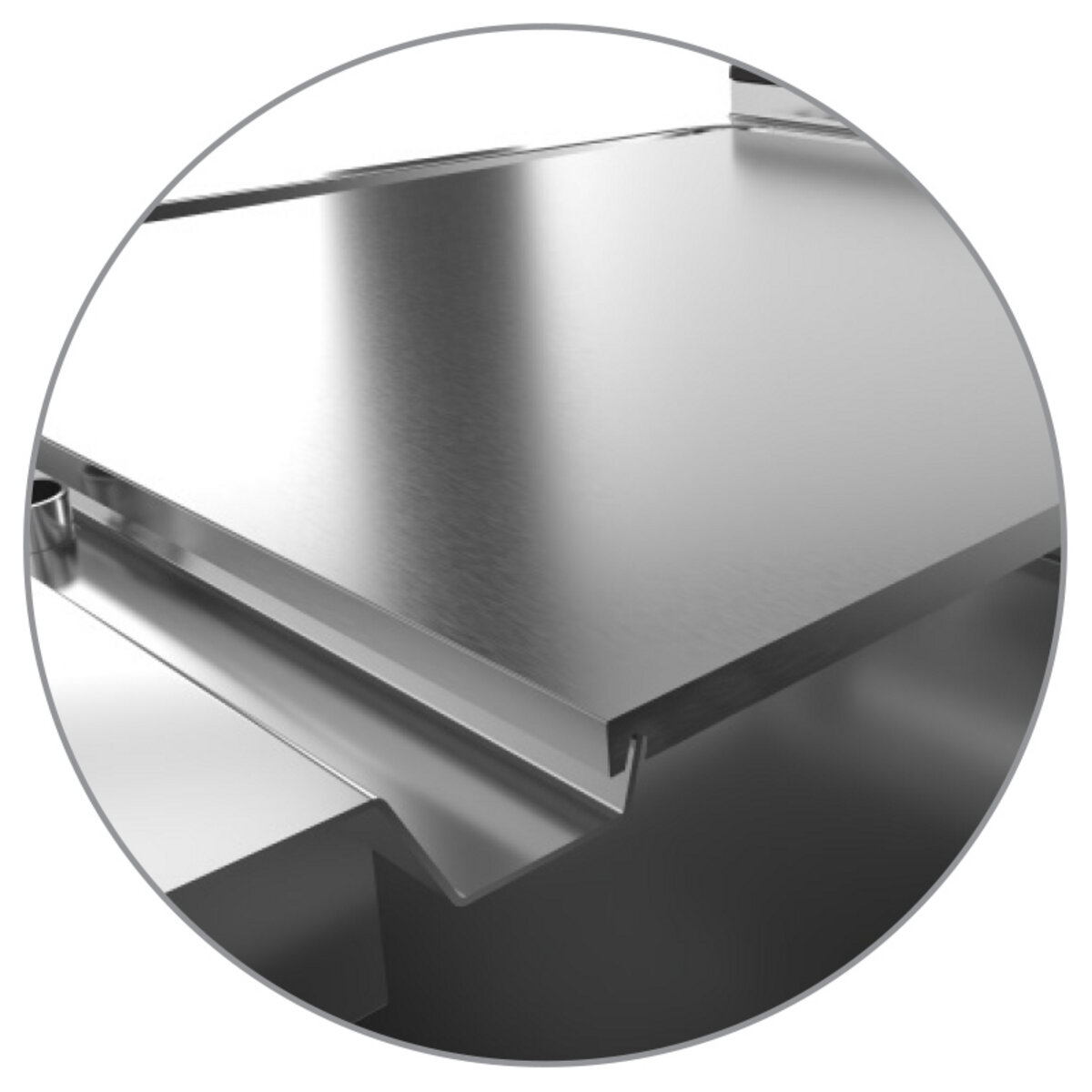

Non-welded plate to speed up maintenance and possible replacement in utilities.

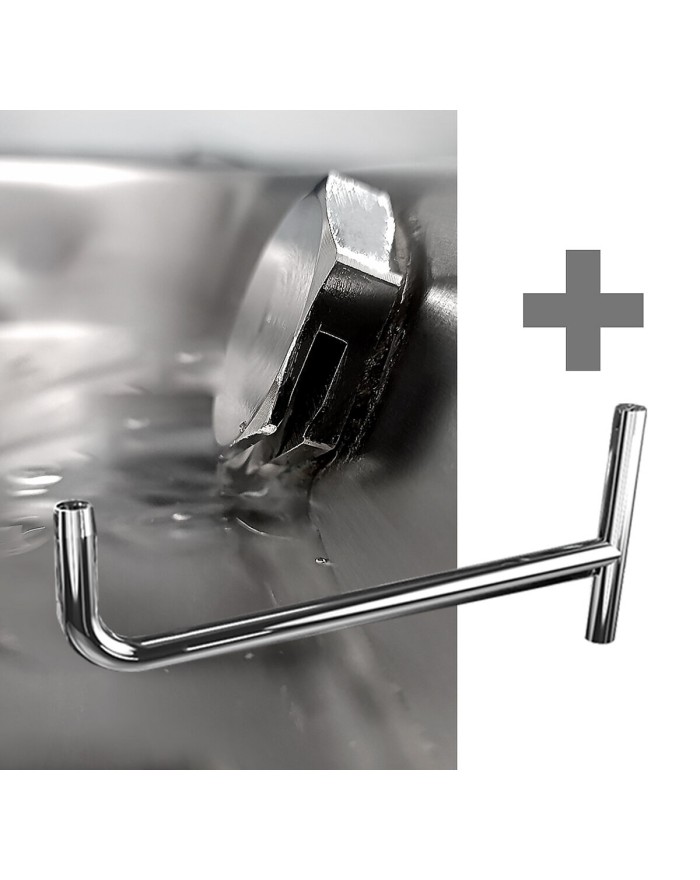

Available as an accessory, the continuous discharge tube allows waste to be disposed of in an external receptacle.

Power level control via touch screen and adjustment with ergonomic knob

Possibility of setting 2 timers to control cooking. An acoustic signal warns the operator at the end of the set time.

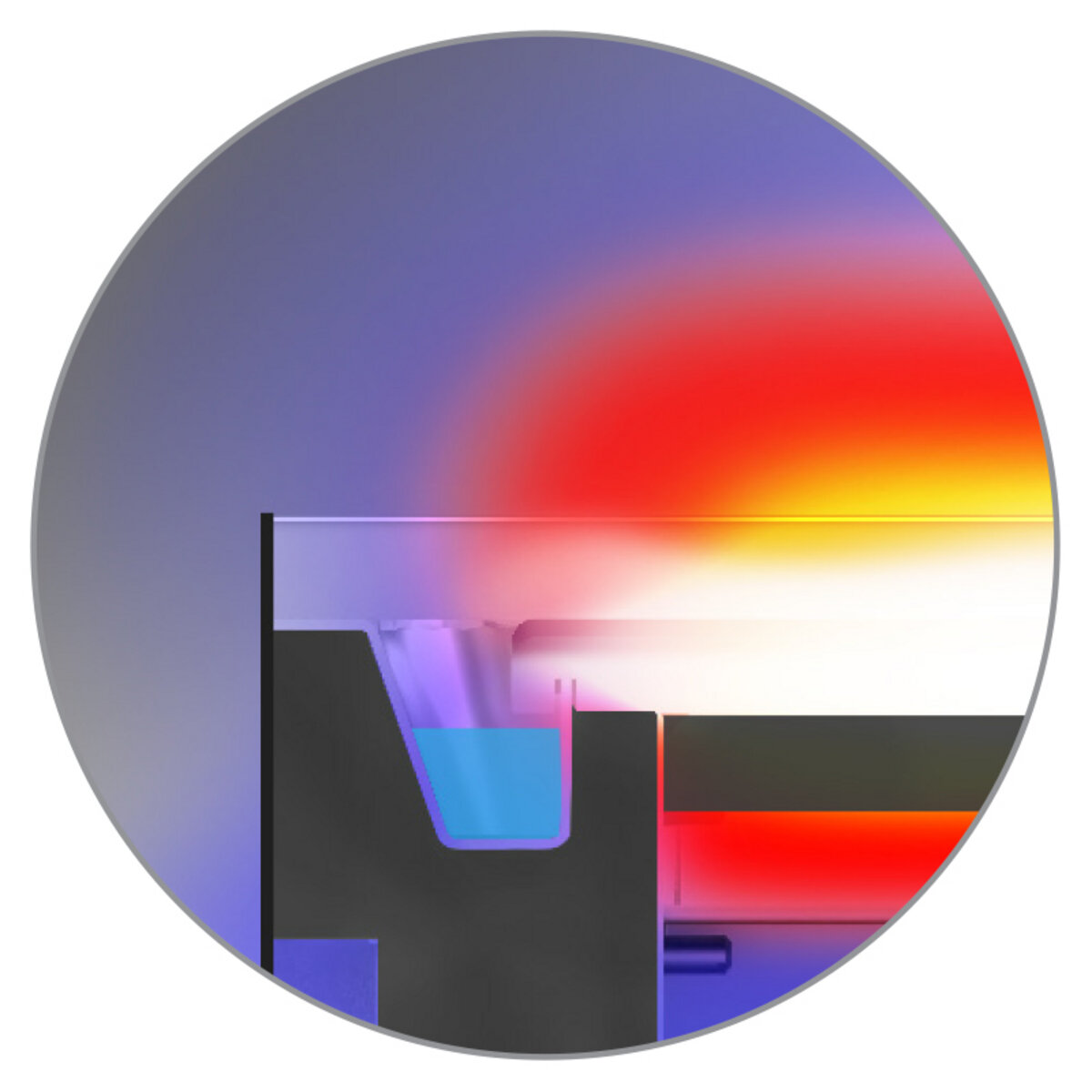

Thermal cutting that facilitates the user and adjacent machinery.

Water dispenser kit available as an accessory

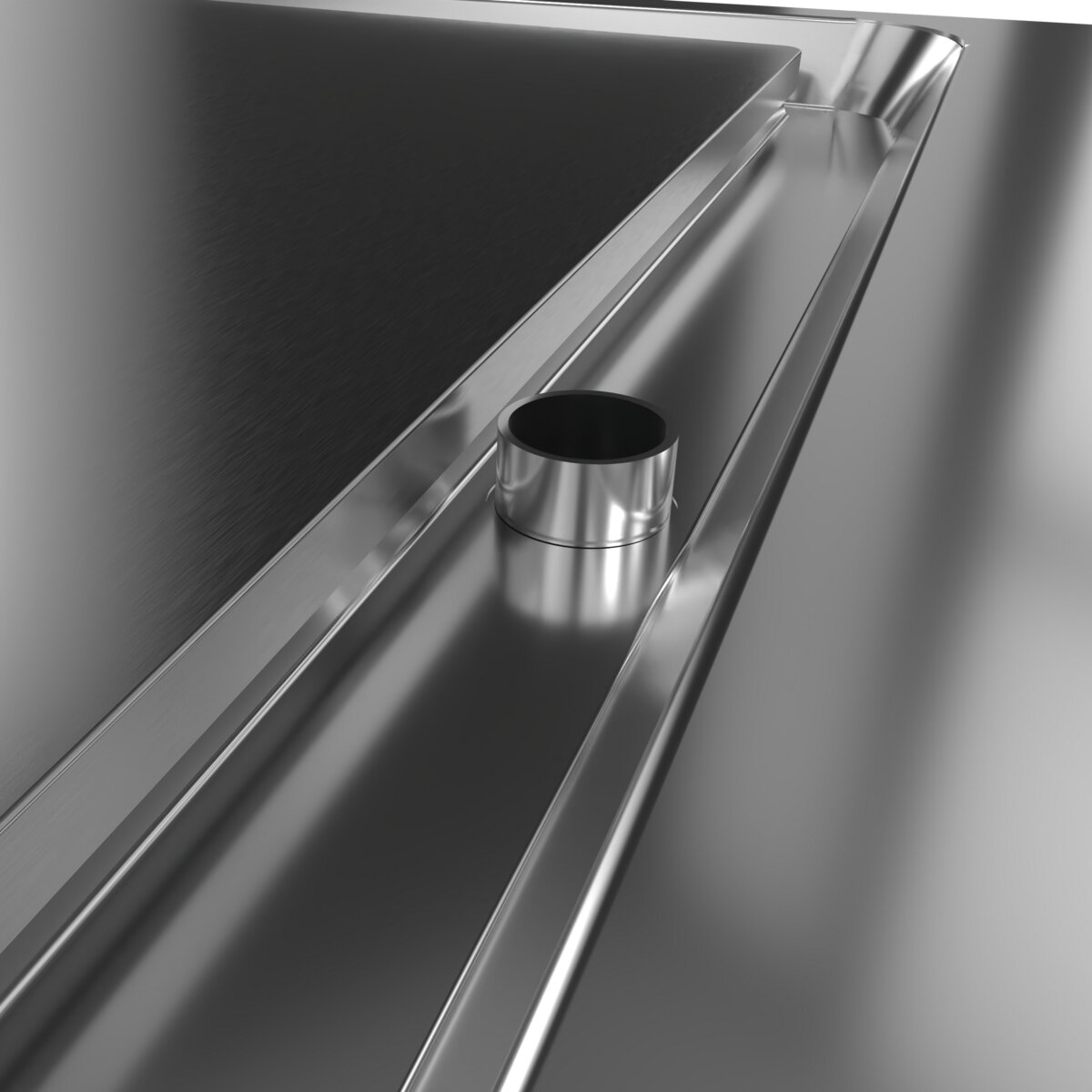

Stainless steel overflow plug provided as standard for gutter flooding management.

Plate not welded to the machine table with optimization of structural points subjected to thermal stress.

Floodable gutter for collecting cooking residue all around the perimeter of the plate easier cleaning, and better moisture retention of cooking food.

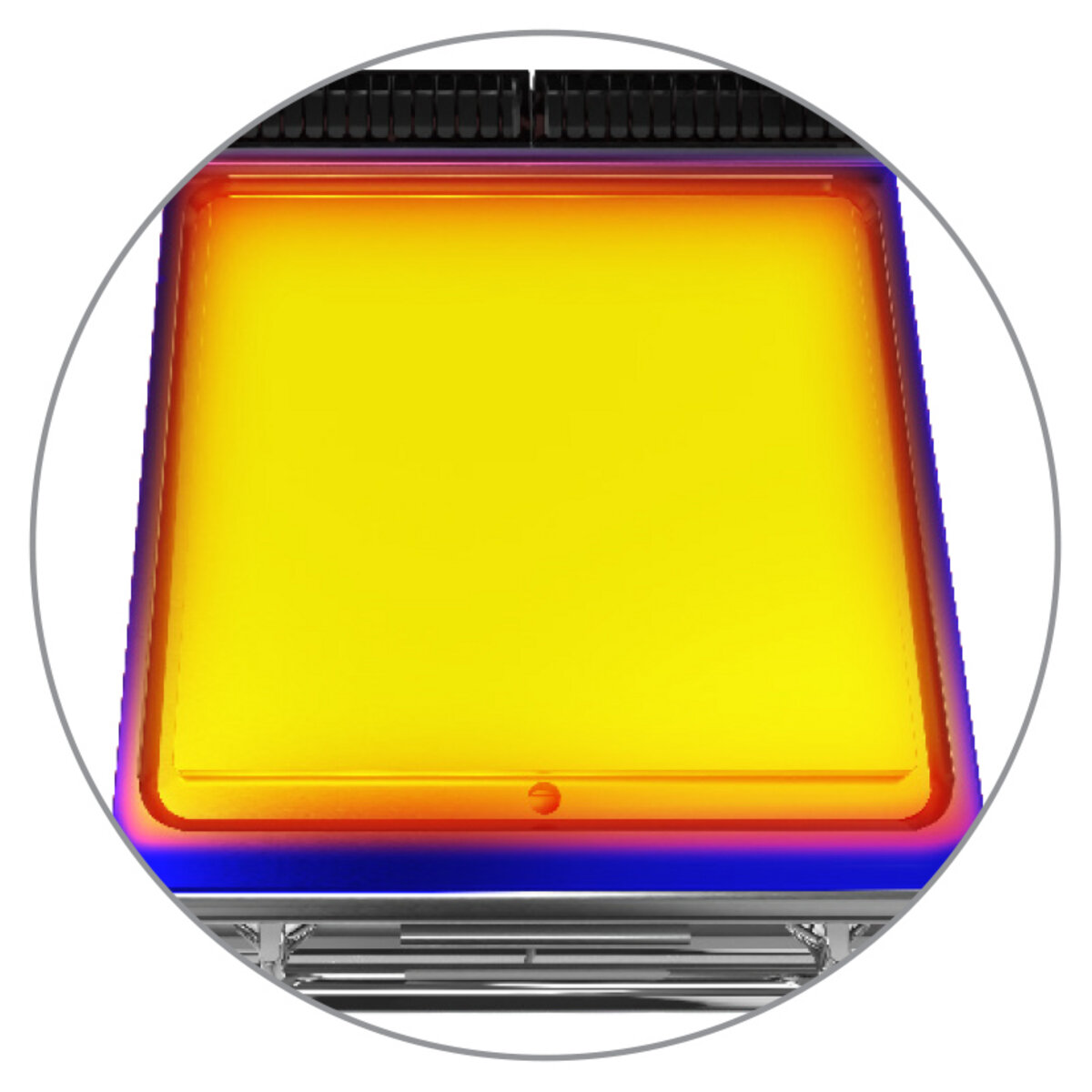

Uniform cooking temperature across the entire plate. Optimising heat in the cooking area and increasing operator comfort in the kitchen.

Capacious grease collection drawer with capacity of the entire volume of the perimeter channel.

Predisposition for core probe, for even greater cooking control. Reaching the set core temperature is signalled by an acoustic signal.

Data sheet

- Model

- QT90SFT/E410-T4W

- CODE

- CR1654699T4W

- Height

- 250mm

- Width

- 400mm

- Depth

- 900mm

- Company

- 0232

- Alimentazione

- ELETTRICA

- Tipo piastra

- RIBBED

- Electrical power

- 7.5Kw

380-415V 3N - Materiale Piastra

- IRON

- Controllo

- THERMOSTATATE

Specific References

- mpn

- QT90SFT/E410-T4W

You might also like

English

English